Much has happend since August of last year. I’m going to post several slide shows now to recap!

Finally decided it was time for a custom fit cover

Finally decided it was time for a custom fit cover

Enderle Birdcatcher mechanical fuel injection replace carbs once blower is installed

Enderle Birdcatcher mechanical fuel injection replace carbs once blower is installed The QuickFuel carbs that were planned for use with the blower are now on the tunnel ram.

The QuickFuel carbs that were planned for use with the blower are now on the tunnel ram.

Under seat controls include fuel shut off, Casale Shift, Fuel Prime.

Under seat controls include fuel shut off, Casale Shift, Fuel Prime.

Butterfly steering dash includes radio transmit, oil and temp alarm as well as Lenco shift.

Butterfly steering dash includes radio transmit, oil and temp alarm as well as Lenco shift.

A fuel primer system was installed. This uses the transfer pump and a solenoid to load the Carbs and purge air from fuel lines after maintenance. This system will eventually be used to prime the fuel injection system which will be disclosed in upcoming slideshow.

A fuel primer system was installed. This uses the transfer pump and a solenoid to load the Carbs and purge air from fuel lines after maintenance. This system will eventually be used to prime the fuel injection system which will be disclosed in upcoming slideshow. System loads fuel rail. Check valves are used to prevent back flow.

System loads fuel rail. Check valves are used to prevent back flow.

Clean installation now includes GPS Speedometer which can be swapped with cellphone for selfie cam

Clean installation now includes GPS Speedometer which can be swapped with cellphone for selfie cam Intercom helmet connections with dust/moisture protectors on.

Intercom helmet connections with dust/moisture protectors on.

The Ignition system was converted to crank Timing. Advance is locked at 37 Deg.

The Ignition system was converted to crank Timing. Advance is locked at 37 Deg. The Mallory distributor is locked and an MSD starter saver is used to retard timing 10 deg. while RPM's are under 1k.

The Mallory distributor is locked and an MSD starter saver is used to retard timing 10 deg. while RPM's are under 1k. The fuel pump had to be moved slightly to make room.

The fuel pump had to be moved slightly to make room.

A Catalina 2.5 Lb Bottle with regulator is mounting using Jegs brackets

A Catalina 2.5 Lb Bottle with regulator is mounting using Jegs brackets The Casale is shifted using a Cippard Pneumatic valve (switch) located under the drivers seat.

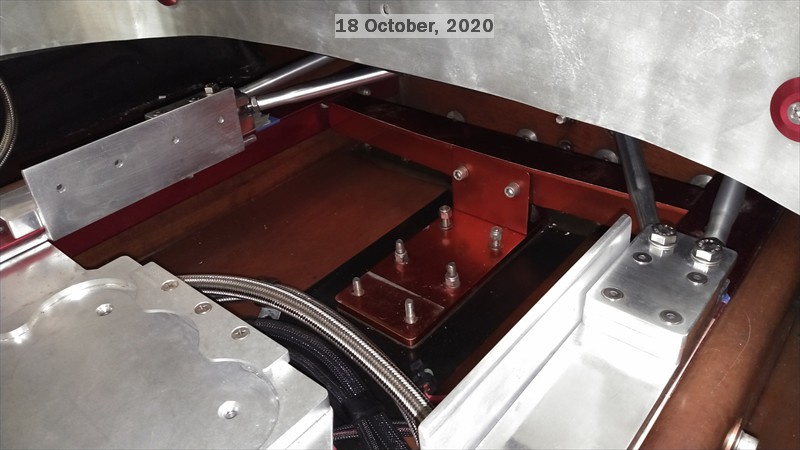

The Casale is shifted using a Cippard Pneumatic valve (switch) located under the drivers seat. A Solenoid is activated with a switch on the butterfly steering to shift the Lenco

A Solenoid is activated with a switch on the butterfly steering to shift the Lenco

Dual secondary regulators will provide the 95lb for the Casale shifter and 150lb required by the Lenco

Dual secondary regulators will provide the 95lb for the Casale shifter and 150lb required by the Lenco

Since CO2 is being installed to shift the Lenco why not go with air shift for the Casale.

Since CO2 is being installed to shift the Lenco why not go with air shift for the Casale. Braided stainless 3AN lines were used instead of cheaper polly tubing.

Braided stainless 3AN lines were used instead of cheaper polly tubing.

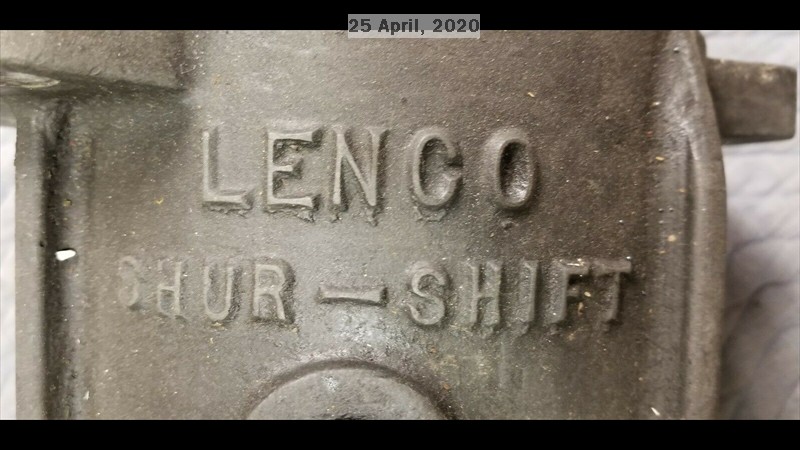

An Owens bell housing and Lenco CS1 transmission have been purchased and will be added after I get a few runs on the water without it.

An Owens bell housing and Lenco CS1 transmission have been purchased and will be added after I get a few runs on the water without it. Here is the CS1 as purchased with what I beleive is a Chevy crank button

Here is the CS1 as purchased with what I beleive is a Chevy crank button  The output shaft is 16 Spline.

The output shaft is 16 Spline. The unit came with an air shift pod already installed

The unit came with an air shift pod already installed

The input shaft shown here with the Chevy crank Button is 10 Spline

The input shaft shown here with the Chevy crank Button is 10 Spline The first of two 460 Crank buttons purchased is shown here fitted on the input shaft. Note the size difference compared to the Chevy part now on the floor.

The first of two 460 Crank buttons purchased is shown here fitted on the input shaft. Note the size difference compared to the Chevy part now on the floor.

Based on the markings the ratio should be 1.31

Based on the markings the ratio should be 1.31

A greek Coupling will be used to connect the Lenco CS! to the Casale.

A greek Coupling will be used to connect the Lenco CS! to the Casale. I will need to upgrade the Casale input shaft to 32 spline. Some adjustments to the motor mounts may also be necessary

I will need to upgrade the Casale input shaft to 32 spline. Some adjustments to the motor mounts may also be necessary

Evolution 2020

Radius Rod anchors were fabricated and rods were installed to beef up the transom.

Radius Rod anchors were fabricated and rods were installed to beef up the transom. It was determined that there should be two structural brackets between the prop strut and the stringer rails. A second was fabricated and installed.

It was determined that there should be two structural brackets between the prop strut and the stringer rails. A second was fabricated and installed.

Much has happend since August of last year. I’m going to post

Several Slide shows now to recap!

Evolution 2020

Finally decided it was time for a custom fit cover

Finally decided it was time for a custom fit cover

Enderle Birdcatcher mechanical fuel injection replace carbs once blower is installed

Enderle Birdcatcher mechanical fuel injection replace carbs once blower is installed The QuickFuel carbs that were planned for use with the blower are now on the tunnel ram.

The QuickFuel carbs that were planned for use with the blower are now on the tunnel ram.

Under seat controls include fuel shut off, Casale Shift, Fuel Prime.

Under seat controls include fuel shut off, Casale Shift, Fuel Prime.

Butterfly steering dash includes radio transmit, oil and temp alarm as well as Lenco shift.

Butterfly steering dash includes radio transmit, oil and temp alarm as well as Lenco shift.

A fuel primer system was installed. This uses the transfer pump and a solenoid to load the Carbs and purge air from fuel lines after maintenance. This system will eventually be used to prime the fuel injection system which will be disclosed in upcoming slideshow.

A fuel primer system was installed. This uses the transfer pump and a solenoid to load the Carbs and purge air from fuel lines after maintenance. This system will eventually be used to prime the fuel injection system which will be disclosed in upcoming slideshow. System loads fuel rail. Check valves are used to prevent back flow.

System loads fuel rail. Check valves are used to prevent back flow.

Clean installation now includes GPS Speedometer which can be swapped with cellphone for selfie cam

Clean installation now includes GPS Speedometer which can be swapped with cellphone for selfie cam Intercom helmet connections with dust/moisture protectors on.

Intercom helmet connections with dust/moisture protectors on.

The Ignition system was converted to crank Timing. Advance is locked at 37 Deg.

The Ignition system was converted to crank Timing. Advance is locked at 37 Deg. The Mallory distributor is locked and an MSD starter saver is used to retard timing 10 deg. while RPM's are under 1k.

The Mallory distributor is locked and an MSD starter saver is used to retard timing 10 deg. while RPM's are under 1k. The fuel pump had to be moved slightly to make room.

The fuel pump had to be moved slightly to make room.

A Catalina 2.5 Lb Bottle with regulator is mounting using Jegs brackets

A Catalina 2.5 Lb Bottle with regulator is mounting using Jegs brackets The Casale is shifted using a Cippard Pneumatic valve (switch) located under the drivers seat.

The Casale is shifted using a Cippard Pneumatic valve (switch) located under the drivers seat. A Solenoid is activated with a switch on the butterfly steering to shift the Lenco

A Solenoid is activated with a switch on the butterfly steering to shift the Lenco

Dual secondary regulators will provide the 95lb for the Casale shifter and 150lb required by the Lenco

Dual secondary regulators will provide the 95lb for the Casale shifter and 150lb required by the Lenco

Since CO2 is being installed to shift the Lenco why not go with air shift for the Casale.

Since CO2 is being installed to shift the Lenco why not go with air shift for the Casale. Braided stainless 3AN lines were used instead of cheaper polly tubing.

Braided stainless 3AN lines were used instead of cheaper polly tubing.

An Owens bell housing and Lenco CS1 transmission have been purchased and will be added after I get a few runs on the water without it.

An Owens bell housing and Lenco CS1 transmission have been purchased and will be added after I get a few runs on the water without it. Here is the CS1 as purchased with what I beleive is a Chevy crank button

Here is the CS1 as purchased with what I beleive is a Chevy crank button  The output shaft is 16 Spline.

The output shaft is 16 Spline. The unit came with an air shift pod already installed

The unit came with an air shift pod already installed

The input shaft shown here with the Chevy crank Button is 10 Spline

The input shaft shown here with the Chevy crank Button is 10 Spline The first of two 460 Crank buttons purchased is shown here fitted on the input shaft. Note the size difference compared to the Chevy part now on the floor.

The first of two 460 Crank buttons purchased is shown here fitted on the input shaft. Note the size difference compared to the Chevy part now on the floor.

Based on the markings the ratio should be 1.31

Based on the markings the ratio should be 1.31

A greek Coupling will be used to connect the Lenco CS! to the Casale.

A greek Coupling will be used to connect the Lenco CS! to the Casale. I will need to upgrade the Casale input shaft to 32 spline. Some adjustments to the motor mounts may also be necessary

I will need to upgrade the Casale input shaft to 32 spline. Some adjustments to the motor mounts may also be necessary

Radius Rod anchors were fabricated and rods were installed to beef up the transom.

Radius Rod anchors were fabricated and rods were installed to beef up the transom. It was determined that there should be two structural brackets between the prop strut and the stringer rails. A second was fabricated and installed.

It was determined that there should be two structural brackets between the prop strut and the stringer rails. A second was fabricated and installed.